Palletized Racking Systems

Space Optimization at Its Best

Unlock the full potential of your warehouse height with our narrow aisle palletized racking system. This specialized system is operated by narrow aisle trucks, offering a range of benefits that optimize your warehouse’s storage capacity.

Specialized Narrow Aisle Trucks: Our narrow aisle racking system is designed to work seamlessly with specialized narrow aisle trucks (man-up), enabling efficient loading, unloading, and order picking from pallets, even at elevated heights of up to 14,000 mm

Direct and Quick Access: Enjoy direct and rapid access to every pallet stored within the system. This ensures that your inventory is easily accessible whenever needed, streamlining your warehouse operations

Maximum Space Utilization: Make the most of your warehouse space with this system. Its narrow aisle design allows for maximum space utilization, helping you store more inventory while optimizing your warehouse’s footprint.

Storage and Order Picking Efficiency: One of the standout advantages is the ability to use the same racking system for both storage and order picking. This dual-purpose functionality enhances efficiency and reduces the need for multiple systems.

With our narrow aisle palletized racking system, you can elevate your warehouse operations to new heights—literally. Experience the advantages of efficient access, space optimization, and dual-purpose functionality to meet your storage and order picking needs.

Our Drive-in/Drive-Through racking system is the epitome of space optimization. It’s the perfect choice for businesses looking to make the most of their available storage space, both horizontally and vertically.

Efficient SKU Storage: This system excels at storing numerous pallets with the same SKU (Stock Keeping Unit), streamlining inventory management and reducing the need for excessive aisle space.

Aisle Elimination: Say goodbye to traditional aisles between racks. With the Drive-in/Drive-Through system, aisles are eliminated, allowing you to store more products within the same footprint.

Seasonal Storage: This system is especially well-suited for seasonal goods storage. It enables you to efficiently manage and access seasonal inventory, optimizing your warehouse space year-round.

Operational Flexibility:

Choose between LIFO (Last In First Out) or FIFO (First In First Out) operation based on your specific inventory handling requirements.

With our Drive-in/Drive-Through racking system, you not only maximize your storage space but also gain the flexibility to adapt to different inventory scenarios. Whether you need efficient seasonal storage or streamlined access to consistent SKU pallets, this system delivers the benefits you need.

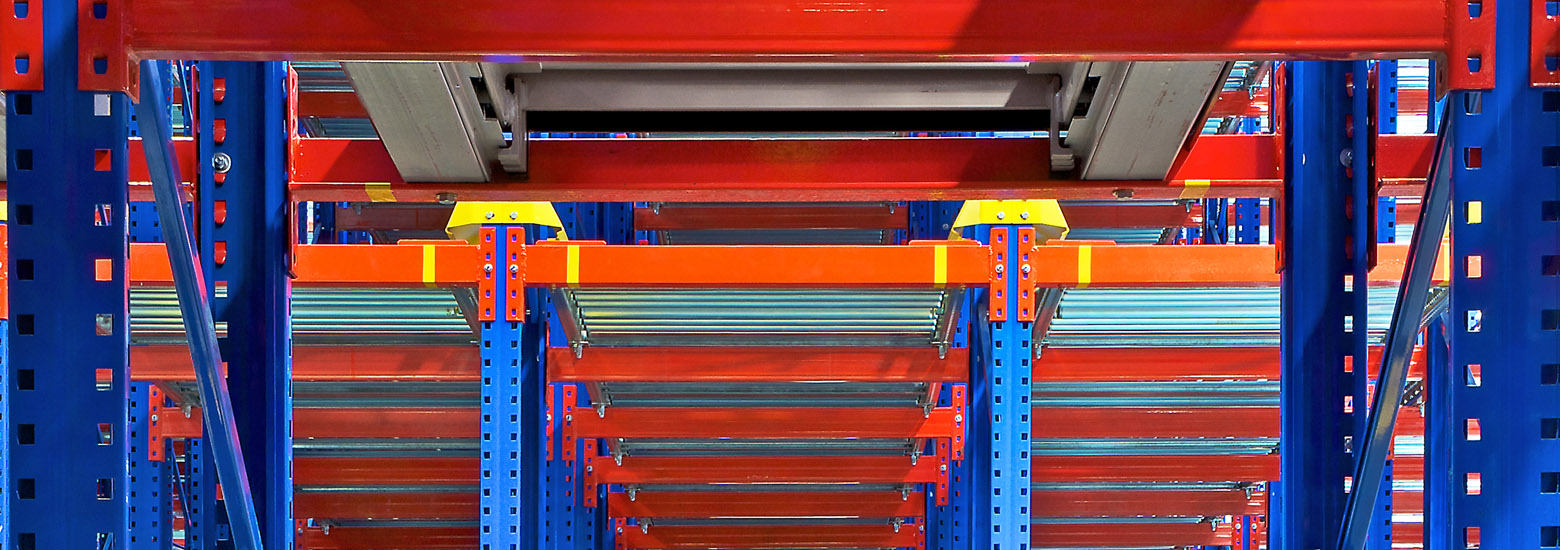

The Pallet Flow Rack system operates on the well-known FIFO (First In First Out) principle, ensuring that products are seamlessly rotated and that the oldest items are picked first. This system relies on the force of gravity to gently guide pallets along roller conveyors from the loading (feeding) side to the unloading (discharge) side.

Gravity-Guided Pallet Movement: Pallets effortlessly glide along roller conveyors with a gentle 4% slope, eliminating the need for manual pallet movement within the rack.

Loading and Unloading from Different Sides: This system allows for loading and unloading from separate sides of the rack, enhancing operational efficiency and product rotation.

Ideal for Perishable Goods: Pallet Flow Racks are particularly well-suited for perishable goods or items with short lifespans. The FIFO principle ensures that products are used in the order they were received, simplifying inventory control.

- 100% FIFO Application: With the Pallet Flow Rack system, the FIFO principle is applied consistently, ensuring that older products are dispatched first. This is essential for managing perishable goods and ensuring product freshness.

- Optimized Warehouse Space: This system makes the most of available warehouse space by utilizing gravity to move pallets, eliminating the need for additional aisle space.

- Efficient Order Picking: Picking orders becomes a faster and more efficient process with the goods being brought directly to the picker (good to man), reducing labor and time costs.

- Streamlined Inventory Control: The FIFO principle simplifies inventory control, making it easy to manage products with shorter shelf lives or those prone to spoilage.

The Pallet Flow Rack system not only maximizes space and efficiency but also ensures product freshness and streamlined inventory management, making it an ideal choice for businesses dealing with perishable goods or products with a short shelf life.

Our Push Back racking system offers a high-density storage solution that allows you to store pallets in the depth direction, much like the drive-in racking system. This system is designed with the LIFO (Last In First Out) principle, meaning that the most recently loaded pallet is the first to be removed.

Key Features

Two Options for Versatility: The Push Back racking system provides you with two different options. The roller option enables the storage of up to 9 pallets in depth, while the trolley option accommodates up to 6 pallets.

Efficient Loading: In the roller option, the forklift gently pushes the next pallet backward over the rollers after placing the first pallet in the lane. This process continues as each new pallet is placed, effectively stacking pallets in the depth of the system.

Gravity-Assisted Unloading: Unloading is facilitated by retrieving the last loaded pallet, which triggers a gravity-assisted movement of the other pallets toward the loading/unloading position.

Benefits

- LIFO Application: The Push Back system strictly adheres to the Last In First Out (LIFO) principle, making it an ideal choice for businesses that prioritize the use of their most recently received goods.

- Maximum Space Utilization: This system effectively utilizes the available warehouse height, allowing you to make the most of your vertical storage space.

- Safety: The Push Back system creates a safe working environment by eliminating the need for forklift operators to enter the racking system, reducing the risk of accidents.

The Push Back racking system offers both efficiency and safety, ensuring that your warehouse operations run smoothly while optimizing storage space. With LIFO application and space utilization in mind, this system is a valuable addition to any warehouse.

The Conventional Pallet Racking system is a versatile and widely used warehouse storage solution that accommodates various types of products. Its hooked beam design allows for easy adjustment of level heights, making it a flexible choice for pallet storage and order picking within the same construction.

Versatile Storage: This system is suitable for storing a wide range of products, making it a go-to choice for businesses with diverse inventory needs.

Height and Layout Customization: The layout and height of the racking system can be customized based on the specific products to be stored, available warehouse space, and the type of forklifts to be used.

Efficient Storage and Retrieval: The Conventional Pallet Racking system allows for both efficient pallet storage and straightforward order picking, streamlining warehouse operations.

- Direct Pallet Access: With this system, you can access each pallet directly, ensuring quick and easy retrieval of products as needed.

- Weight and Size Flexibility: The Conventional Pallet Racking system is adaptable to the weight and size of items to be stored, providing a flexible solution for varying inventory requirements.

- Dual-Purpose Shelving: This system enables you to use the same shelving for both storage and order picking, optimizing space and enhancing efficiency.

- Wide Range of Accessories: A variety of accessories are available to enhance the functionality of the system, allowing you to further tailor it to your specific needs.

The Conventional Pallet Racking system offers adaptability, efficiency, and direct access to pallets, making it a versatile choice for businesses with diverse storage requirements. With customization options and a range of accessories, it can be tailored to your unique warehouse needs.

Non – Palletized Racking Systems

Space Optimization at Its Best

When it comes to storing long, bulky, and variously sized items like pipes, bars, profiles, and boards, the Cantilever Racking System stands as the most suitable choice. This system is specially designed to accommodate products of different weights, using a combination of materials to ensure optimal performance.

Weight-Based Design: The Cantilever Racking System is engineered with materials chosen according to the weight of the goods to be stored. It uses cold-formed profiles to support lighter weights and employs hot-rolled materials such as IPE and NPI for heavier items.

Structural Integrity: The system is composed of console arms bolted to vertical structural columns and reinforced with bracings, ensuring the structural integrity needed to support long and bulky items.

Adjustable Length: Cantilever racking systems can be easily adjusted to the desired length using additional elements, providing flexibility in accommodating various product sizes.

- Ideal for Long Bulky Items: This system excels at storing long and bulky items, making it perfect for businesses dealing with pipes, bars, profiles, and more.

- Flexible Level Heights: You can easily adjust the level heights to accommodate changes in product sizes or storage needs, ensuring efficient use of space.

- Modular Extension: Thanks to its modular construction, the Cantilever Racking System offers the possibility of extension, allowing you to adapt as your storage requirements evolve.

The Cantilever Racking System is the go-to choice for businesses that need to efficiently store and access long and bulky items. With its weight-based design and adjustable features, it provides the flexibility and durability required for effective storage solutions

The Light and Medium Duty Shelving system is designed for warehouses and facilities where various-sized boxed products with light to medium weights are manually loaded and unloaded. This system is particularly well-suited for the storage of products that vary in size and have medium volume and weight

Versatile Storage: The system is ideal for accommodating products of different sizes with medium volume and weight, providing a flexible solution for various inventory needs.

Efficient Product Access: It offers direct and quick access to products, making it easy to retrieve items whenever needed.

Customizable Shelf Levels: Shelf levels can be customized based on your requirements and can be covered with materials like galvanized or painted metal decks, hardboard, plywood, or MDF.

Mezzanine Design: The elements of the Light and Medium Duty Shelving system can be used to design a mezzanine system, adding further storage or workspace.

- Efficient Product Access: The system provides easy and direct access to products, making it suitable for applications where the FIFO (First In First Out) principle is applicable.

- Ideal for Boxed and Loose Products: Whether you’re storing boxed or loose products, this system is a versatile choice that can accommodate both.

- Modular Construction: Its modular construction allows for easy changes and adjustments, ensuring flexibility as your storage needs evolve.

The Light and Medium Duty Racking System is a versatile solution for businesses that need to store various-sized products with medium weights. With efficient product access and customizable features, it offers the flexibility required to manage different inventory types effectively.

Flow Racks for Boxes provide an efficient and organized solution for storing containers and other items. These racks use roller tracks that rely on the force of gravity to move loads, ensuring a constant supply of goods to the working area. Loading and unloading can be performed from different sides of the rack module, adding to the system’s versatility.

Gravity-Powered Rollers: Roller tracks, powered by gravity, enable the seamless movement of goods, optimizing the supply of products to the working area.

Dual-Sided Accessibility: The system allows for loading and unloading from different sides of the rack module, enhancing efficiency and flexibility.

Versatile Application: Flow racks for boxes can be incorporated into various conventional racking systems, making them suitable for a wide range of storage environments.

- FIFO or LIFO Application: The system supports both FIFO (First In First Out) and LIFO (Last In First Out) principles, providing flexibility in managing inventory.

- Efficient Order Picking: Flow racks expedite the order picking process, bringing products directly to the worker (good to man), which reduces labor time and effort.

- Simplified Inventory Control: Easy inventory control is another advantage of this system, ensuring that you can manage your stock effectively.

Flow Racks for Boxes are an ideal choice for businesses that prioritize efficient order picking, dual-sided accessibility, and flexible inventory control. Whether you need to adhere to FIFO or LIFO principles, this system provides the versatility needed to streamline your storage and retrieval processes.

Automated Systems

An Automated Storage and Retrieval System (AS/RS) is a dedicated storage system that combines computer-controlled technology with warehouse management system (WMS) integration to automate the storage and retrieval of loads from predefined storage locations.

AS/RS systems are adaptable to both heavy and light loads. UNITLOAD is ideally suited for heavy and bulky items stored on pallets, containers, and similar items. On the other hand, MINILOAD is designed for light and small-volume items, such as totes, boxes, and cartons. The loading and unloading of products within these systems are performed by stacker cranes, and the entire operation is controlled by a computerized system.

Key Features

Load Versatility

AS/RS systems cater to a wide range of loads, from heavy and bulky items to smaller, lightweight products.

Stacker Crane Operation

Stacker cranes efficiently manage the loading and unloading of products within the system, ensuring precise handling.

Computerized Control

The entire AS/RS system operates under computerized control, offering a high degree of precision and automation.

Benefits

- Real-Time Inventory Control: AS/RS systems offer a 100% accuracy level in real-time inventory control and updates, ensuring you always have an accurate account of your stock.

- High Speed and Accuracy: These systems operate at maximum speed and provide a high level of accuracy, enhancing overall efficiency.

- Safety: The fully automatic operation of AS/RS systems contributes to high levels of human and material safety.

- Space Optimization: AS/RS systems effectively increase the efficiency of existing storage space, making the most of your available resources.

Semi – Automated Systems

The Shuttle Racking System is a semi-automated racking solution that shares similarities with drive-in racking in terms of its construction. However, what sets it apart is its unique method of loading and unloading pallets. This is achieved through a remote-controlled shuttle that moves along specially designed rails connected to the racking channels.

Key Features

Remote-Controlled Shuttle: The system utilizes a remote-controlled shuttle that transports pallets within the racking system, allowing for efficient loading and unloading.

Deep Storage: Pallets are stored in the depth direction of the system, maximizing both space and height utilization. This enables the storage of different products within the same channel.

Ideal for Cold Warehouses: The Shuttle Racking System is particularly suitable for cold warehouses where investment costs tend to be higher due to its ability to make the most of available space.

- Space Optimization: This system excels at optimizing space usage, making it a wise choice for businesses seeking to maximize storage efficiency.

- Versatile Storage: The ability to store different SKUs in the same channel adds to its versatility, allowing you to manage various product types efficiently.

- Aisle Elimination: By eliminating the need for aisles between the racking, you can further enhance space utilization and improve efficiency.

- Cost Advantages: The Shuttle Racking System offers cost advantages in terms of both labor and equipment, reducing operational expenses.

- Safe and Fast Operation: The system provides a safe and rapid operation method, contributing to a productive and secure warehouse environment.

The Shuttle Racking System is a semi-automated solution that offers high space optimization, versatile storage options, and cost advantages, making it an excellent choice for businesses looking to streamline their warehousing operations, especially in cold storage facilities.

Special Racking Solutions

Space Optimization at Its Best

Mezzanine Racking is a specialized multi-tiered system designed to create additional workspace within a warehouse or industrial facility. It achieves this by utilizing heavy or light-duty shelving systems in combination with accessories like walkways, railings, stairs, loading doors, and more.

Multi-Tier Design: Mezzanine Racking allows for the creation of multiple tiers or levels within the warehouse, effectively increasing available workspace.

Customization: The system offers design flexibility to meet specific needs, allowing you to tailor the mezzanine to your unique requirements.

Versatile Flooring: Shelf levels and walkways can be covered with a variety of materials, including plywood, steel grating, MDF, chipboard, platform sheet, and more.

Dismountable and Reusable: Mezzanine floors are designed to be fully dismountable and reusable. Their structure, dimensions, and location can be easily modified as needed.

- Increased Workspace: Mezzanine Racking Systems are highly effective in expanding workspace within warehouses and industrial facilities, optimizing available square footage.

- Design Flexibility: The system offers a wide range of design possibilities to accommodate specific requirements, ensuring it meets your unique needs.

- Modular Construction: The modular construction of mezzanine floors allows for extensions and modifications, adapting to changing needs over time.

Mezzanine Racking Systems are a valuable solution for businesses seeking to maximize workspace within their warehouse or industrial facility. With design versatility, customizable flooring options, and the ability to adapt to evolving requirements, these systems offer an effective means of optimizing available space.

Rack Clad Buildings, also known as SILO, are specially designed racking systems that serve as the supporting structure for an entire construction. These unique structures can be built using various racking systems, including conventional pallet racking, narrow aisle, shuttle, drive-in, dynamic, and more.

Integration of Racking: Rack Clad Buildings integrate the racking system into the entire structure, eliminating the need for separate supporting columns and trusses.

Compact Design: The compact design of these buildings is attractive for its space-saving capabilities, making efficient use of available space.

Compatibility: Rack Clad Buildings can be configured to work with both conventional and automated material handling equipment, providing flexibility in warehouse operations.

Modularity: The modularity of these structures allows for the possibility of relocating the entire warehouse if needed, offering adaptability to changing requirements.

- Space Savings: Rack Clad Buildings are designed to maximize space efficiency, making them an ideal choice for businesses looking to optimize their available storage area.

- Equipment Compatibility: These structures can work seamlessly with various material handling equipment, whether manual or automated.

- Modular and Movable: The modularity of Rack Clad Buildings enables easy reconfiguration or relocation of the warehouse, providing long-term flexibility.

Rack Clad Buildings, or SILO, offer an innovative approach to warehousing by integrating the racking system into the building structure. With their compact design, equipment compatibility, and modularity, they provide an efficient and adaptable solution for optimizing storage space and warehouse operations.

The Compact Archive Racking System is a mobile racking solution designed for storing files and similar products, offering maximum utilization of your archive area while requiring only a single aisle for access.

Mobile Design: The Compact Archive Racking System consists of units mounted on bases equipped with wheels. These bases move along tracks mounted on the floor, providing mobility to the racks.

Direct Access: The system allows for direct access to each file, ensuring efficient retrieval of archived documents.

Versatility: With minor modifications and additional accessories, these racks can also be adapted for the storage of different products, enhancing their versatility.

- Space Efficiency: The Compact Archive Racking System excels in space-saving, making it an excellent choice for organizations seeking to maximize their archive area.

- Ergonomic and User-Friendly: The system is designed for simplicity and ease of use, providing an ergonomic solution for managing archived materials.

- Single Corridor Requirement: Only a single aisle is needed for access, reducing the floor space required for archive storage.

- Safe and Efficient: The system offers safe and fast operation, contributing to a productive and secure archive environment.

The Compact Archive Racking System is a practical and efficient solution for organizations dealing with a large volume of archived files and documents. Its mobile design, direct access capabilities, and adaptability make it a valuable addition to any archive management strategy.

Accessories

Effective storage solutions often require a range of accessories to optimize organization, protection, and presentation. Here are some essential accessories for various storage solutions:

Our wire shelves come with a variety of accessories to customize your shelving to suit the storage needs of any business or industry, regardless of size. These include casters, liners, and covers to enhance functionality. If you require even more flexibility, our post parts and individual shelves allow you to create your own unique shelving configurations, compatible with our standard wire shelving offerings.

Pallet rack protection is crucial for preventing costly maintenance charges, workplace accidents, and damage to stored stock. It also helps businesses comply with health and safety regulations by absorbing daily impacts and protecting against bumps and knocks from warehouse vehicles. This creates a safer working environment for all.

Dividers are essential for effectively separating shelves or wire shelves into different sections, promoting greater organization. Each item can have its designated space, simplifying inventory management and stocking.

Regardless of your retail style, we offer a variety of data strips and hardware accessories designed to create an organized and clean look throughout your warehouse or store aisles. These products are designed to meet the highest expectations of your customers, enhancing the overall shopping or browsing experience.

These accessories play a vital role in optimizing your storage solutions, ensuring efficient organization, protection, and presentation of items in a wide range of industries and businesses.

Our comprehensive line of trolleys is designed to meet the diverse needs of businesses across various industries. Whether you require trolleys for transporting long parts and products, handling sensitive materials, or facilitating efficient picking within your warehouse, we have you covered.

Key Features

Versatile Range: Our trolley collection spans a wide range of applications, addressing the specific needs of different businesses. We offer trolleys suitable for various tasks and industries.

Custom Design: In addition to our standard trolley offerings, we have the capability to design and manufacture trolleys tailored to your unique requirements. This ensures that your trolleys are perfectly suited to your business’s operations.

Quality and Durability: Our trolleys are built to meet high-quality standards, ensuring longevity and reliable performance in demanding environments.

- Adaptability: Our diverse selection of trolleys allows you to choose the right tool for the job, promoting efficiency and productivity within your operations.

- Tailored Solutions: If your business has specific trolley needs, we have the expertise to design and manufacture custom trolleys that align with your exact requirements.

- Quality Assurance: You can trust in the quality and durability of our trolleys, which are designed to withstand the rigors of daily use.

From handling long parts to transporting sensitive materials and optimizing warehouse picking, our trolley solutions are designed to enhance your business’s operational efficiency and meet your unique needs.